2.5M PRESS TECHNOLOGIES - HYMAC WETLAP MACHINE MODEL 100 HP-SF WITH HEAVY DUTY PRESS COMPLETELY REBUILT 2018

2.5M PRESS TECHNOLOGIES - HYMAC WETLAP MACHINE MODEL 100 HP-SF WITH HEAVY DUTY PRESS COMPLETELY REBUILT 2018

Description

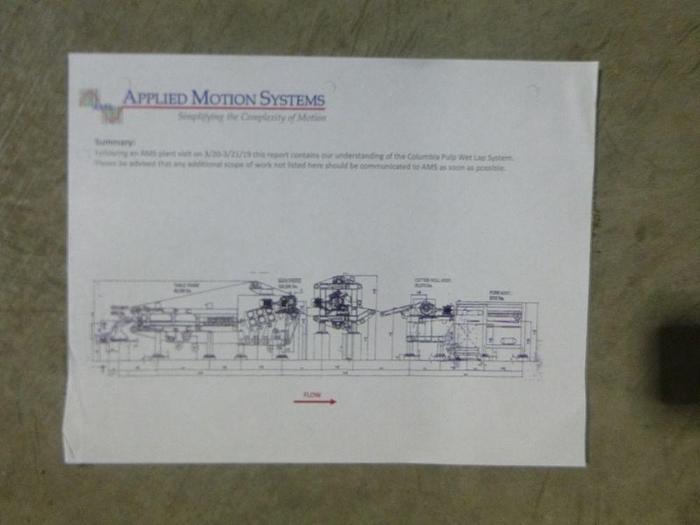

One (1) Used Press Technologies - Hymac Model 100 Wet Lap Twin Wire Press, Model 100 HDP Heavy Duty Press, and Model 100 Cutter Layboy. Line rebuilt by Press Technology in 2018. New electrical and control system. Rated 200-400 TPD Desired Capacity When Installed 400 ODSTPD Inlet Consistency: 3.5-4.5% OD Discharge Consistency: 45+2% OD Temperature >130 Degrees F HDP HEAVY DUTY SECONDARY PRESS The thickened pulp sheet from a primary Twin Wire Press is transferred onto the bottom wire of the PRESS TECHNOLOGIES model HDP SECONDARY PRESS unit and is carried up and into the large press nips. Pressure is achieved pneumatically using Firestone air bags, with a performance design pressure up to 1200 PLI. High performance roll covers are generally used for superior durability and performance at these pressures. The moisture removed in the nip will commonly raise the pulp consistency, depending on operating conditions, about 4-6% or more. Pressate is doctored away and fed into drain pans incorporated in the unit for discharge according to customer requirements. After pressing, the pulp travels down to a discharge roll, at which point it can be transferred to a Cutter Layboy unit, sent to a drying line, or handled in some other fashion.

Specifications

| Manufacturer | HYMAC |

| Model | WETLAP MACHINE |

| Condition | Used |

| Stock Number | 904301.015 |

| Inlet consistency | 3.5-4.5% OD |

| Discharge consistency | 45+2% OD |

Documents

- columbia-puchase-order-17-0010-hdp-section-pdf

- ptwl-2-5-1001d-p-id-flow-schematic-1_sht-1-of-3-1-pdf

- ptwl-2-5-1000e-sht-1-pdf

- operation-and-general-description-columbia-pulp-2-5-meter-wet-lap-system-pdf

- hdp-100-1000c-pdf

- columbia-puchase-order-17-0009-wet-lap-rebuild-pdf

- 500-1410-121-rev0-gen-arrangement-sh-2-pdf